The Areas Come to Life

The “Cave”

The primary shop area was referred to as the “cave” because, when we first saw it, our flashlight could not see one end from the other. The original plan was to put the machine shop, woodworking shop and classroom in it. When Gene joined and brought the railroad, a model shop was added. The cave had to be wired and lighted and walls built for the shops, which took nearly a year to complete. As with most “geek” groups, changes were constantly occurring so it could never be really be considered complete.

The wiring was a team effort. Rich bought a Ramset and put up most of the junction boxes, Michelle and Warren ran conduit and wire and connected everything and Dan was the lighting guru. Over 60 four foot florescent lights were found on Craigs list. Dan went through them, consolidated parts to make working fixtures and hung them in the cave and common areas.

Machining

The first area to actually become fully usable was the machine shop. In January 2012, we got some power on the cave East Wall so that the mill and lathe could be used. It took several more weeks before they were leveled and set up to go. The major equipment in it are a lathe, CNC mill, bandsaw, and drill press. Between Rich and Warren, there were numerous small tools as well. Vic donated a good amount of material (steel, aluminum, and brass) to the shop.

Room Construction

Next to be done was the construction of the classroom and model shop. Gene furnished the material for the model shop and money was raised for the classroom. We wanted a large window to view the railroad in the model shop and Joe furnished one.

Work on the rooms seemed to drag on forever, but finally, with Joe and Gene leading, the walls started up. Rich did most of the wiring for the room walls and some serious head scratching as an outlet box was completely covered up by drywall. Seth arranged for us to get some flooring from Habitat for Humanity (many thanks to them) so that we could have decent wood floors in the rooms. We did expect any day to find that a forklift had crashed through our ceiling into one of the rooms, but that was finally reinforced and the rooms started to take shape. They were ready early in the Summer.

Woodworking

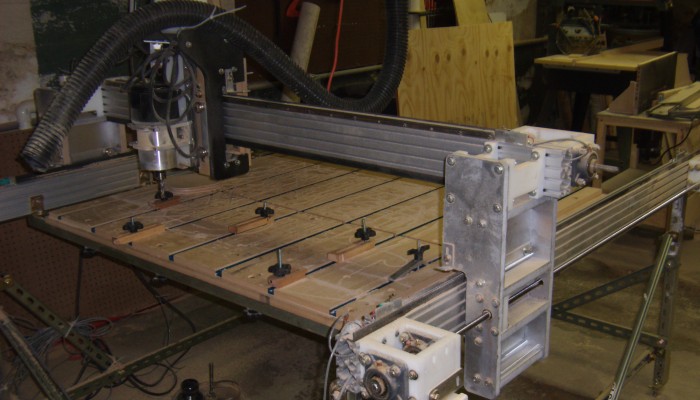

The woodworking area was possibly the last to become useful, but later became the most productive. We had only a few items at the December 2011 open house. Joe brought in a few more, but it was only after Ross and Rick became active that it really became useful. Besides the circular saw, radial arm saw and planer (operational), we had a sander, bandsaw, router table, scroll saw, lathe and jointer. A dust system had been installed and two CNC routers were operational. The shop was used to make much of the Fright night props, a Cinderella carriage for a high school play, a sleigh for the December open house in 2012, a “cart of the dead” for a local production of Spamalot, a boat for “Willy Wonka” and several personal projects.

In early 2016, an Industrial 24″ Bandsaw was obtained. Later, a 18″ Drum Sander, an 18″ Molder, an oscillating sander, and a slide-miter saw were donated. In early 2017, a second lathe was purchased and several other lathes were loaned so that woodturning classes became practical.

Classroom

As soon as we decided on the size of the space, the idea was to have a classroom for training. Initially, it was to be built out of a portion of the cave with the remainder being the machine area. After the inclusion of the model shop, the classroom and model shop were built at the same time.

The classroom was roughly 20×30 feet and had an “instructor” desk and eight dual student stations. We could not afford an official whiteboard, so we made one from white formica. It may not last as long as the “professional” boards, but at a cost of $8, could be easily replaced as it wears out. A projector and sound system were also scrounged. There was also a rack for network training that will be used for those classes. It was also one of the areas to benefit from the flooring donated by Habitat.

Since becoming active in the Summer of 2012, the classroom was used for classes in machining, blender, CAD, Inkscape, ham radio, electronics, locksport, programming, microprocessors, soldering and robotics. Air conditioning, was being installed as of May 2017.

Due to grants, the classroom was now equipped with 17 current laptop computers complete with touch screens and there were 17 commercial grade Soldering rework stations. A grant was also furnishing new chairs for the classroom which were planned to be obtained in the Summer of 2017. The classroom was available for external groups to use as well.

The HO Railroad

The main item in the model shop is the HO scale railroad which was brought in by Gene. It was at his house and had to be dis-assembled, moved and re-assembled. Gene and a crew were able to do so early in the Summer, then Gene recruited Warren to help put it back together. There was a lot of detailed work on the railroad and the tracks needed to be aligned so it took quite a while. It was operational and impressive, but Gene, in the true Hacker spirit, constantly added on and tweaked it. He also had the materials to create scenery and accessories for the railroad (and other models).

Gene is also an expert in static electricity control and has a setup to measure and demonstrate electrostatic discharge.

Common Area

The former “office” became the Common Area. It contained a Lounge, the Electronics Shop, the Ham Radio station, a “Kitchen”, the bathroom, and several general tables.

The common area was on an outside wall with three large west facing windows of “crinkle glass” and an alcove that extends beside a neighboring space. Originally, the alcove was set up as a tiny office and, at meetings, everyone would sit with their backs to the windows due to the brightness of the sun. Shortly after FCW moved in, Dan painted the area and re-floored the bathroom. In the Summer of 2012, we covered the inside of the windows with mylar covered styrofoam sheets which helped with the blindness and some with the heat. Early in the Summer of 2013, we put a window air conditioner in to help with the heat. With additional flooring from Habitat, a wood laminate floor was installed in 2013 as well. At that time, the area was re-arranged so that the alcove became a tiny Kitchen. Finally, in early 2014, after months of negotiation, we got a high speed Internet connection from Charter Communications. In 2016 the windows were insulated and sealed, helping with the air conditioning and heat.

Electronics Shop

The electronics area became operational soon after our first open house. There was a reasonable set of equipment at the space, including a Pace surface mount re-work station, Thermoflo , several oscilloscopes, meters, and function generators. We had several trainers and can work with numerous microprocessors and digital devices. Early in 2014, Blue Ridge Energies donated several anti-static benches which were installed in the area. They also donated two 19 inch racks, which, along with some server donations from Google, became various network servers. In late 2015 and early 2016, several RF spectrum analyzers, RF and audio signal generators, multi-channel oscilloscopes, power supplies, and A/V analysis equipment were donated and a grant furnished 17 professional soldering rework stations.Over the years, thousands of parts were donated, and cataloged but were not organized. In early 2017, an additional electronics “parts area” was created in the cave and parts cabinets installed. As of May 2017, most of the parts had been sorted and organized and a database was being created.

Library

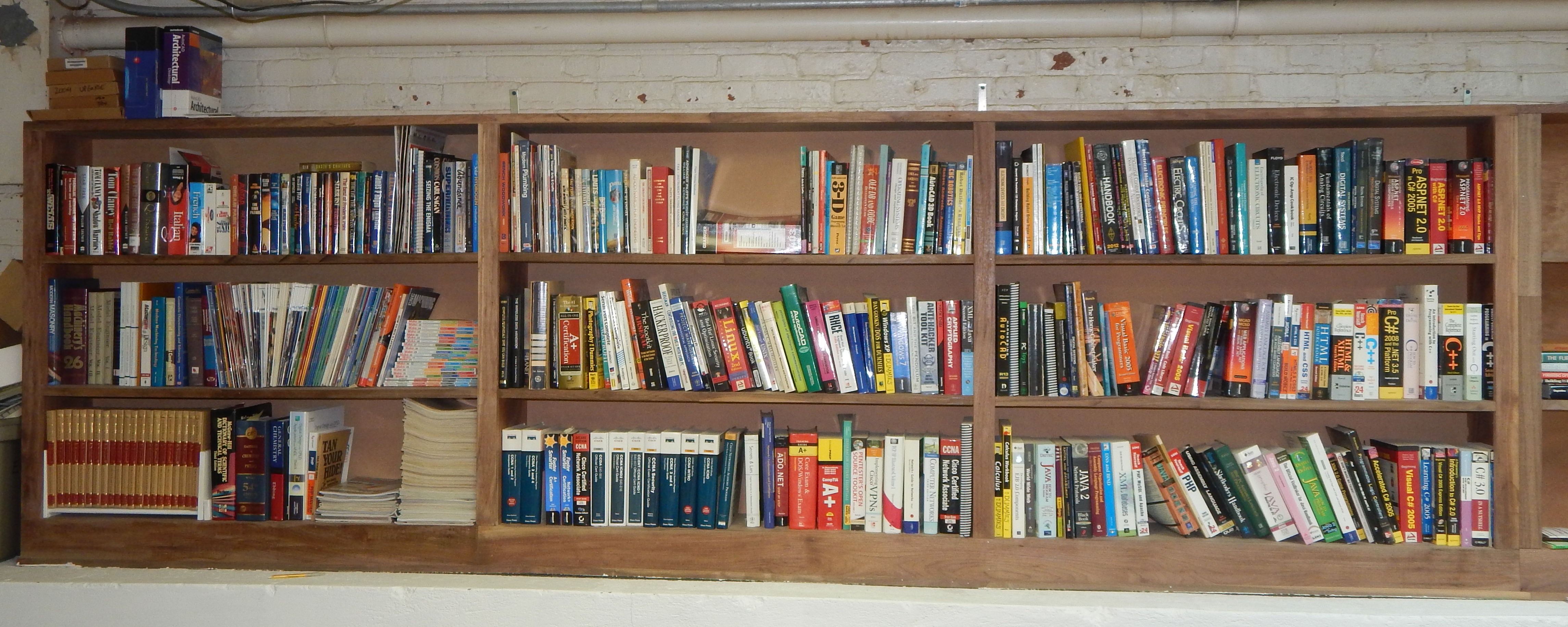

Somewhere along the line, Dan (I think) brought in some books to start a library. Then Dan, Michelle, Rich, and later JD, Derek, and Ross populated the library so that it contained books, on computers, operating systems, programming languages, micro-controllers, analog and digital electronics, physics/chemistry/math, networking, machining, geek fiction and other topics. The original library occupied a portion of the common area. In 2016, shelves were built in the classroom and the library moved to it. It became apparent that the new shelves would soon be outgrown as well so plans were to build additional shelves on the back wall of the classroom.

Somewhere along the line, Dan (I think) brought in some books to start a library. Then Dan, Michelle, Rich, and later JD, Derek, and Ross populated the library so that it contained books, on computers, operating systems, programming languages, micro-controllers, analog and digital electronics, physics/chemistry/math, networking, machining, geek fiction and other topics. The original library occupied a portion of the common area. In 2016, shelves were built in the classroom and the library moved to it. It became apparent that the new shelves would soon be outgrown as well so plans were to build additional shelves on the back wall of the classroom.

Ham Radio

Michelle and Colin are Amateur Radio operators. After Buck joined and Dan got his Ham license, we started a Ham station. Michelle and Colin furnished most of the equipment so that we had HF and VHF capability. Ross, JD, Ben, Ernesto, Adam and Bruce, Mike W., Mitch, and Jared are also hams and several more are interested in getting a license. We got a station call of K4FCW and participated in four field days and several contests. The station had HF and VHF multi-mode capability and added digital modes. The station containd two HF radios, one HF/VHF/UHF multimode radio, and a 2m/6m/70cm radio. There was a dipole antenna, a Cushcraft AR270 2m/70cm antenna, a Cushcraft R5 vertical mounted on a beam about the loading dock and a Butternut HF9V vertical on the roof. We were not allowed to fasten anything to the roof so the antennas were held in place with large rubber feet on tripods and sandbags.

Michelle and Colin are Amateur Radio operators. After Buck joined and Dan got his Ham license, we started a Ham station. Michelle and Colin furnished most of the equipment so that we had HF and VHF capability. Ross, JD, Ben, Ernesto, Adam and Bruce, Mike W., Mitch, and Jared are also hams and several more are interested in getting a license. We got a station call of K4FCW and participated in four field days and several contests. The station had HF and VHF multi-mode capability and added digital modes. The station containd two HF radios, one HF/VHF/UHF multimode radio, and a 2m/6m/70cm radio. There was a dipole antenna, a Cushcraft AR270 2m/70cm antenna, a Cushcraft R5 vertical mounted on a beam about the loading dock and a Butternut HF9V vertical on the roof. We were not allowed to fasten anything to the roof so the antennas were held in place with large rubber feet on tripods and sandbags.

Kitchen

The “kitchen” started out as a dorm sized refrigerator brought in by Michelle for the first open house. Since there was no air conditioning, it was used to store bottled water. After the open house, we decided that we needed a way to snack, so we bought a used microwave oven. After Ross joined, he brought in a popcorn machine. When the Common Area was redone with the floor, the opportunity was taken to improve on the kitchen area. The alcove, formerly used as an office was re-purposed. A larger refrigerator was brought in and coffee pots and several small items added. Plans were to enhance it so that those who travel a distance could use it instead of having to find a restaurant. A toaster oven and griddle were added and a cabinet was constructed to organize everything. In 2016 a sink was added (with filtered water). Even though the kitchen was small, we were able to fix sufficient meals for occasional events and allow members to eat without having to get fast food.

Lounge

The lounge was a popular “hang out and chew the fat” area. It was the common area, but there were some items specifically for it. Starting out with the aforementioned couch, we added a few of the better chairs from the auctions. Dan scrounged a large CRT TV and dvd player, and CJ donated a stereo to start it off. In May 2013, Michelle obtained a large TV cart at auction, then Michelle, Dan, and Derek scrounged several console games, including a Sega, Xbox, Xbox 360, PS, PS2, and Wii along with several games for relaxing. In late 2013, a friend of Colin donated a large LCD TV, which was hung on the wall. In June 2014, we added a DTV antenna to the roof so the TV could receive 38 channels, along with playing dvds and acting as a large display. Ross built a Mame machine in early 2013 which was being re-built for dual controls.

In 2016, a much better couch was donated so the former one was returned to the “building”. A 5.1 surround sound system was installed in May 2017.

Storage

After the 2012 Fright Night (Halloween), it became obvious that we needed more storage. In early 2013, our landlord started building and renting storage units in the building. One of the units was directly opposite our cave entrance and shared external doors with FCW. We worked out a deal with the renter to move to another one and added that storage unit – approx 16×20 ft to our space. In 2014, we made free standing shelving modules for it to increase efficiency.

Fabrication Lab

One notable area of the building was directly across from the entrance to our common area. This area had originally been part of a large restroom but had been cut off and made into a separate room for some kind of storage in the cotton mill. Still, relics of the original restroom remained in that the had red ceramic tile on the floor and three walls, and had a floor drain. The ceiling was finished and insulated. There were two huge cabinets in it that the landlord allowed us to move to the cave for use. The landlord was planning to fix the area up as an office for rent.

When FCW approved the laser cutter in the Summer of 2013, we also decided to rent the “tile room” to be the eventual home of the laser cutter and other activities that needed external exhaust since it had an exterior wall. It was nearly three months before we had the room ready for the laser cutter but it was set up for the laser cutter, the 3d printers, and laminator. in 2016, a second, smaller laser cutter was purchased and a work area set up. With the rental of the Fab Lab, FCW had all areas accessible from our external doors. The landlord allowed us to use the lobby area joining the various areas for temporary purposes.

Auxillary Area 1

In December 2014, FCW acquired some additional space adjacent to and connected to the “cave”. It was a “lease it or forget it forever” situation, so we grabbed the opportunity. The space consisted of two rooms. One was 20×24 ft and the other 20×20 ft giving a total of 880 sq ft of additional space. Both rooms were on an outside wall, giving an additional 6 windows for external access. As seems to be our lot in life, one of the rooms had no power at all and the other had a single circuit that was at least 50 years old. Also, there was no control over the lights, so one of the first tasks was to wire the area. This was mostly completed in July of 2015.

There were several suggestions as to what to put in the new area including: an extension to the woodshop; the science lab, glass shop and ovens (originally destined for the lab) ; a prop/costume shop, a small office; and others. It was decided that the larger area would become a Science Lab and include the sciences (Physics, Chemistry, Biology), the ovens, and glassblowing. The smaller area would become a Stagecraft shop (props, sets, costumes). Both areas would also have general work areas.

With this space, FCW has averaged an expansion every 13 months, with the initial space Sept. 2011, storage area Nov. 2012, Fabrication Lab Nov 2013, and Auxillary space Dec. 2014.

Science Lab

As mentioned above, the larger of the Auxillary areas was converted into a science lab. It was intended to have chemistry, physics and biology as well as some support functions. Within a short time it contained a laminar flow hood, 2 heat treating furnaces, a drying oven, an incubator, an autoclave, a toaster oven, a UV/Vis spectrometer, a centrifuge, a micro centrifuge, biological and inspection microscopes and some chemical glassware. Cabinets were installed and a large (former) pizza oven was obtained which was to be converted to multiple purposes. Lab tables were picked up from surplus and a sink was being installed. A grant planned to furnish new chairs for the lab in the Summer of 2017 and a fume hood with external exhaust. Chemicals and other supplies were acquired as funds permitted.

As mentioned above, the larger of the Auxillary areas was converted into a science lab. It was intended to have chemistry, physics and biology as well as some support functions. Within a short time it contained a laminar flow hood, 2 heat treating furnaces, a drying oven, an incubator, an autoclave, a toaster oven, a UV/Vis spectrometer, a centrifuge, a micro centrifuge, biological and inspection microscopes and some chemical glassware. Cabinets were installed and a large (former) pizza oven was obtained which was to be converted to multiple purposes. Lab tables were picked up from surplus and a sink was being installed. A grant planned to furnish new chairs for the lab in the Summer of 2017 and a fume hood with external exhaust. Chemicals and other supplies were acquired as funds permitted.

In early 2016, an old Scanning Electron Microscope was donated. It dated back to the ’70s and had all analog electronics, some of which was missing. The decision was made to discard the electronics and rebuild the SEM with modern circuitry. As of May 2017, the entire vacuum system was running and the coils were being mapped.

In early 2016, an old Scanning Electron Microscope was donated. It dated back to the ’70s and had all analog electronics, some of which was missing. The decision was made to discard the electronics and rebuild the SEM with modern circuitry. As of May 2017, the entire vacuum system was running and the coils were being mapped.

It was hoped that the Science Lab would be used to develop courses for schools, tutor and teach science to students, home schooled students, or anyone else who may be interested.

As an experiment, the Science lab was lit exclusively with LED lighting. It was so successful that LED lighting was planned to replace the lights in the remainder of the space as funds permitted

Stagecraft

Also as mentioned above, the smaller of the Auxillary areas was destined to become a Stagecraft Shop. FCW had worked with stage and similar areas before, building a Cinderella Carriage, a Willy Wonka Boat, and a Spamalot Cart of the Dead, as well as the Fright Nights. Ross is heavily into masks, props and costumes while Michelle has experience in lighting, sound, and SFX. Mitch, Jim, Ron, and several others are interested in various aspects of stagecraft or associated fields (such as photography).

The area originally became a de-facto storage area, and was still being slowly cleaned out but as it started to take shape. Three large tables, some cabinets and shelves were installed. The glass shop was been located here including a glass saw and glassblowing burners. A digital sound board, DMX lighting control, stage lights, and a workbench for SFX and animated props were installed.

In early 2016, a Brother Industrial Sewing machine was donated, capable of sewing canvas and leather as well as normal cloth. This area was also planned to have a renderfarm for digital animation and imaging.

In early 2016, a Brother Industrial Sewing machine was donated, capable of sewing canvas and leather as well as normal cloth. This area was also planned to have a renderfarm for digital animation and imaging.

General Fabrication

It is an unwritten tradition that hackerspaces must have a 3D printer,  so in the Spring of 2012, FCW members raised money to build one. There was quite a bit of discussion on whether to get a parts kit or build everything from scratch. With major work still going on fixing up the space itself, we decided to get a partial parts kit. It was determined that a variation of the Mendel Max II was best so parts were ordered. Michelle had access to a commercial 3D printer so none of the printed parts were ordered. After starting the assembly, some modifications were made and a few printed parts were ordered for the mods due to the commercial printer being unavailable for the Summer. Assembly dragged on as other things got priority. When Dave joined, he took on the task of completing the printer and worked well. Plans were in the works for more printers of different styles. Also, Michelle obtained the carcass of a commercial 3D printer which was being restored to service.

so in the Spring of 2012, FCW members raised money to build one. There was quite a bit of discussion on whether to get a parts kit or build everything from scratch. With major work still going on fixing up the space itself, we decided to get a partial parts kit. It was determined that a variation of the Mendel Max II was best so parts were ordered. Michelle had access to a commercial 3D printer so none of the printed parts were ordered. After starting the assembly, some modifications were made and a few printed parts were ordered for the mods due to the commercial printer being unavailable for the Summer. Assembly dragged on as other things got priority. When Dave joined, he took on the task of completing the printer and worked well. Plans were in the works for more printers of different styles. Also, Michelle obtained the carcass of a commercial 3D printer which was being restored to service.

In the Spring of 2013, Rich provided some seed money for a Laser Cutter. Several members pitched in with additional funds so that we could purchase a larger unit with a more reliable tube. It came in early Summer 2013 and was put in the common area due to needing an outside wall. A few months later, the laser cutter was moved to the Fab Lab and the exhaust fan mounted outside. It was a 90W unit from Full Spectrum capable of precision cuts and engraving on wood, acrylic, leather and cloth, and engraving on glass and stone and was used extensively for many types of projects. Ross obtained some 3mm MDF and some masonite that was used for many items. Rick created numerous wood engraved pictures using it, and FCW sold ham radio callsigns engraved on marble. It wasused for numerous projects, including cutting out the chassis for an affordable robot kit that FCW designed.

In the Spring of 2013, Rich provided some seed money for a Laser Cutter. Several members pitched in with additional funds so that we could purchase a larger unit with a more reliable tube. It came in early Summer 2013 and was put in the common area due to needing an outside wall. A few months later, the laser cutter was moved to the Fab Lab and the exhaust fan mounted outside. It was a 90W unit from Full Spectrum capable of precision cuts and engraving on wood, acrylic, leather and cloth, and engraving on glass and stone and was used extensively for many types of projects. Ross obtained some 3mm MDF and some masonite that was used for many items. Rick created numerous wood engraved pictures using it, and FCW sold ham radio callsigns engraved on marble. It wasused for numerous projects, including cutting out the chassis for an affordable robot kit that FCW designed.

Also in the Spring of 2013, Michelle brought in a small MIG welder capable of welding steel, stainless steel and some aluminum. It was also available in the Fab Lab.

A second, smaller “laser cutter” was purchased in mid 2016. Originally a rubber-stamp engraver, it was being converted into a small laser cutter and being made portable so that it could be taken off site for demos or training.

In Spring 2017, FCW was awarded a grant to get 12 3d Printers, most of which were planned to be set up in mobile workstations to be loaned to the public schools for teaching additive manufacturing. These could also be used for FCW projects and for similar teaching to home schooled students.

Next: Classes and Workshops

Great