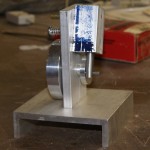

FCW recently offered a Beginning Machining workshop, covering basic Milling, Drilling, and Turning operations. The workshop allowed the participants to make a small air/steam wobbler engine. Rich Goldner was the instructor and there were seven participants in two groups. The workshop took 16 hours spread over 4 weeks.

Raw stock of Aluminum and Steel was used in the project. The base was cut, faced and drilled, the cylinder cut, faced and drilled, and the piston, crank and flywheel turned on the lathe. The CNC mill was used for the milling and drilling operations. Besides the milling, drilling and turning training, the project also involved the setup of the mill and lathe, tapping, and precision measurement.

This workshop was restricted to current members of FCW but another is planned that will be open to the public.