FCW is now a 501(c)(3) approved organization, able to take tax-deductable donations. The paperwork was started in January 2012 and submitted in May 2011. The approval went through without any questions or corrections. Many thanks to those on the committee. Now… to look for grants.

Category Archives: Uncategorized

Nov Sweepstakes

The Lenoir Amateur Radio Club used the Ham radio station at FCW this past weekend to participate in the November Sweepstakes. For portions of Saturday and Sunday Hams across North America made contacts with each other, exchanging locations, calls and a sequence number. FCW is pleased to be able to provide a facility for such events.

The Lenoir Amateur Radio Club used the Ham radio station at FCW this past weekend to participate in the November Sweepstakes. For portions of Saturday and Sunday Hams across North America made contacts with each other, exchanging locations, calls and a sequence number. FCW is pleased to be able to provide a facility for such events.

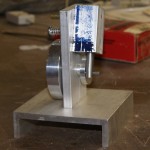

Machining Project

FCW recently offered a Beginning Machining workshop, covering basic Milling, Drilling, and Turning operations. The workshop allowed the participants to make a small air/steam wobbler engine. Rich Goldner was the instructor and there were seven participants in two groups. The workshop took 16 hours spread over 4 weeks.

Raw stock of Aluminum and Steel was used in the project. The base was cut, faced and drilled, the cylinder cut, faced and drilled, and the piston, crank and flywheel turned on the lathe. The CNC mill was used for the milling and drilling operations. Besides the milling, drilling and turning training, the project also involved the setup of the mill and lathe, tapping, and precision measurement.

This workshop was restricted to current members of FCW but another is planned that will be open to the public.

Ham Radio Station Official

The FCW Amateur Radio (HAM) station is now official with the callsign K4FCW. We hope to have antennas up soon. We have HF, VHF and digital capabilities with others to be added in the future. There are plans to offer Ham Radio license classes in the near future.

Room Construction Started

The construction for the classroom and railroad/model shop room has started. Joe, Warren and Gene are starting the construction stage of FCW’s phase 2.

The classroom will allow FCW to provide instruction in numerous topics for up to 24 persons at a time. The model shop will contain a large model railroad – provided by Gene – and a model shop for railroad and RC models.

Machine Shop is On-line

The machine shop is now operational. We have a CNC mill, lathe, bandsaw and grinders. Pictured are Warren, a retired machining instructor, and Rich, who converted the mill to CNC and furnished the equipment.

The shop has already been used to assist a local high school in fabricating parts for a robot. Regular training in Basic Safety and Usage is offered.